Thermal Spray Coatings

Thermal Spray Coatings

Thermal Spray Coatings

Thermal Spray Coatings

Thermal Spray Coatings

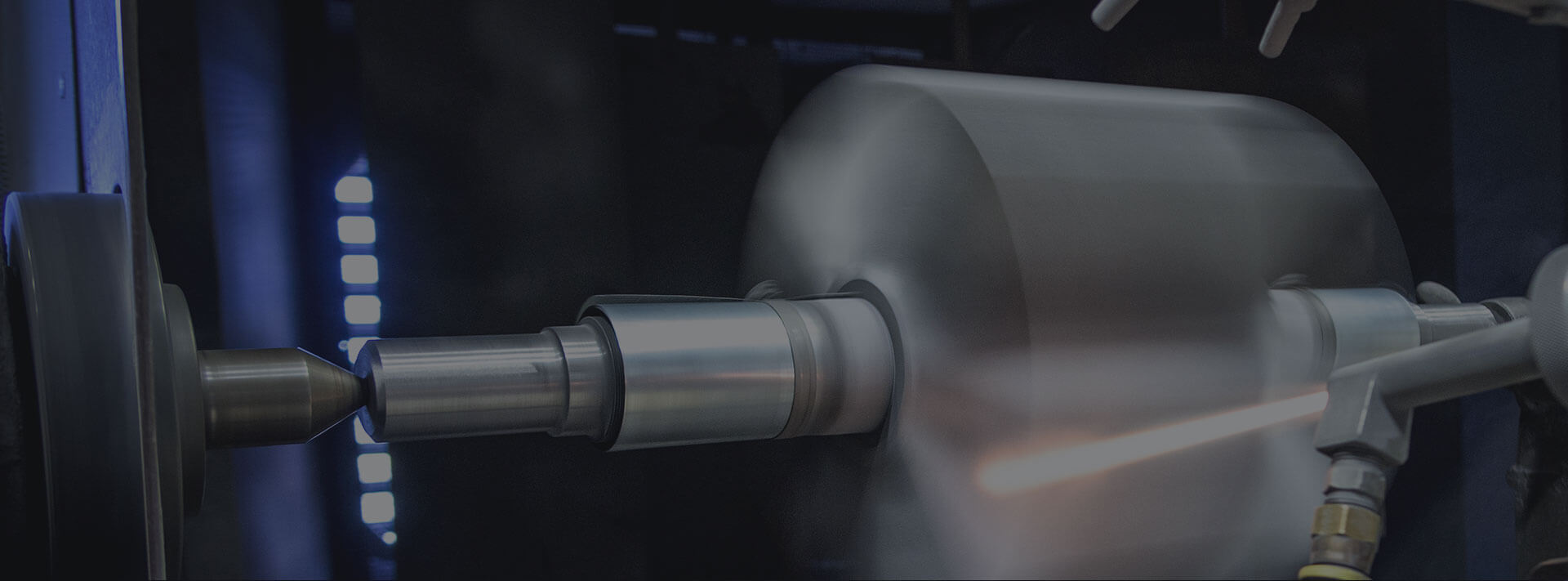

Exline Thermal Spray Coating Systems restore worn components to original dimensions and improve wear resistance, resulting in reduced down-time at a lower cost than fabricating replacement parts. Compare to hard chrome plating.

Learn about the thermal spray options Exline provides.

Coating parts using thermal spray systems provides the following benefits:

- Adds corrosion protection

- Improves lubrication

- Provides an abradable surface creating near-zero running clearance

- Can be utilized to salvage production run under-sizing

Exline Thermal Spray Coating Systems can be used to repair or enhance all of these components:

- Impellers, Fans, and Shafts

- Bearing/Seal Areas

- Crankshafts

- Steam Turbine Shafts

- Hydraulic Rams

- Cylinders

- Pump Components

Exline uses multiple spray systems Improving Lubrication:

- Combustion spray systems

- Twin Arc spray systems

- Plasma spray systems

- High Velocity Oxygen Fuel (HVOF) systems

Thermal Spray coatings can also be applied to "new" parts to make them stronger.

Multiple Coating Options

Exline's Thermal Spray Coating technicians select from hundreds of metallic and nonmetallic coating options to achieve the protective characteristics most appropriate for your production part.

Thermal Spray coatings are applied at our Industrial facility in Salina, KS. For equipment that can’t be moved, Exline field technicians are able to apply thermal spray coatings to parts and equipment on-site as well. For more information go to On-Site Repair and Manufacturing

Learn more about our Industrial Repair and Manufacturing Services

On-Site Equipment Repair and Machining

Learn more about Exline

Request more Information/Get a Quote